Hydraulic Fluid Testing

Performance, contamination and condition monitoring for hydraulic systems — protecting uptime and component life

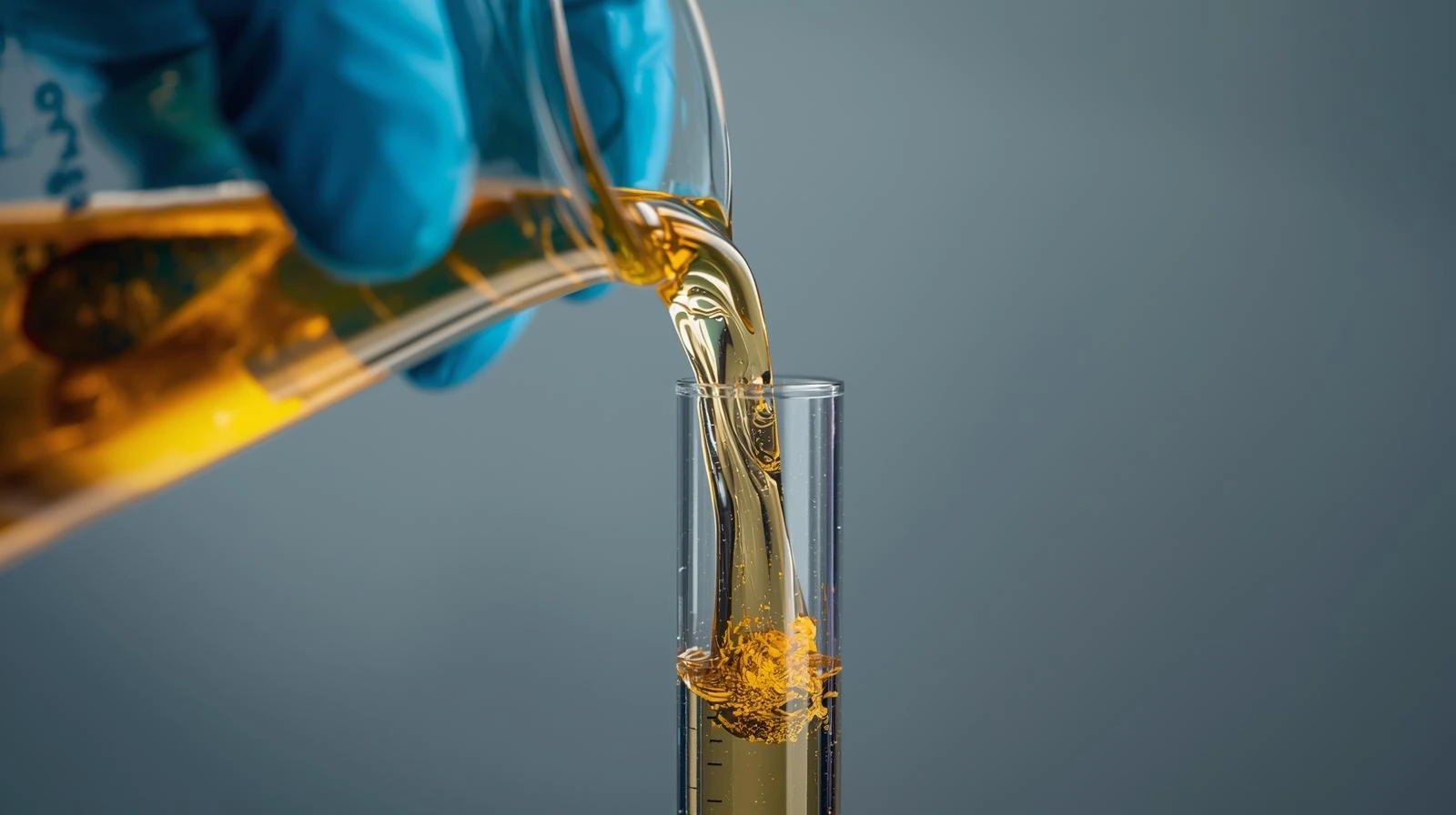

Hydraulic Fluid Testing — Condition Monitoring & Contamination Control

Hydraulic fluid testing are the lifeblood of precision machinery: contamination, oxidation, water ingress or additive depletion can quickly lead to wear, valve sticking, pump failure and unscheduled downtime. AGT Labs provides targeted hydraulic fluid analysis focusing on appearance, contamination indicators, water content, residue, corrosivity and compositional changes — supporting reliable fluid condition assessment and maintenance decisions..

We test mineral, synthetic and biodegradable hydraulic fluids across industries including manufacturing, mobile equipment, turbines, marine systems and offshore operations.

The beneficiaries are OEMs, maintenance teams, reliability engineers, fleet operators, offshore and onshore production facilities.

Service Highlights

- Condition assessment using appearance, color, odor, nonvolatile residue, conductivity and corrosion screening.

- Composition and contamination evaluation through GC-based profiling, gum tendency and refractive index checks.

- Support for maintenance decisions with clarity, cleanliness indicators, residue levels and compatibility observations.

Industries We Serve

- Industrial Manufacturing — presses, injection moulders, machine tools.

- Mobile Equipment — construction, mining and agricultural hydraulics.

- Energy & Offshore — subsea actuators, cranes and riser systems.

- Aerospace Ground Support — high-performance hydraulic systems requiring strict cleanliness.

Laboratory Capabilities & Instrumentation

Analytical Systems

Color and appearance assessment, copper strip corrosion rating, refractive index measurement, non-volatile residue determination, conductivity testing, hydrocarbon composition and detailed GC-based analysis.

Reporting & Advisory

- Cleanliness and purity indicators based on color, corrosion behaviour and residue trends.

- Compositional trend summaries using sulfur patterns, hydrocarbon profiles and refractive index shifts.

- Diagnostic support for contamination events and fluid degradation based on accredited test data.

Sampling, Handling & Chain of Custody

Representative sampling is essential for meaningful condition monitoring. Use clean sampling bottles, in-line sample points (with particle counters where possible), and observe contamination-minimising procedures in hydraulic fluid testing.

Sampling Best Practice

- Use in-line particle counters for real-time monitoring if available.

- Collect samples from system midstream (not tank surface) and after stabilization.

- Label with system ID, operating temp, sample point, date/time and operator.

Sample Volumes & Storage

- Typical 100–500 mL for full panel; larger volumes for retention or multiple tests.

- Avoid headspace; keep samples sealed and ship at ambient unless otherwise specified.

- Retain baseline samples for trending and comparative diagnostics.

Quality Assurance, Reporting & Interpretation

COAs include raw values, trending graphs (if requested) and recommended maintenance actions. We provide numeric thresholds linked to OEM/industry guidance and custom alarm levels for asset managers.

- Deliverables: COA, interpretive comments, trend report (optional), and maintenance recommendations.

- Consultation: On-site sampling training and bespoke monitoring program design.

Standards & Accreditation

Hydraulic fluid testing aligns with ISO and ASTM guidance (ASTM D524, ASTM D2624 , ASTM D2163 etc.). AGT Labs operates to ISO/IEC 17025 quality standards; scope and certificates available on request.

FAQs — Hydraulic Fluid Testing

How often should hydraulic fluid be monitored?

What does ISO 4406 cleanliness code mean?

Can you advise on filtration or flushing?

Deliverables & Value-Added Services

- Metal trends and interpretive commentary.

- Trend reporting and fleet dashboards (on request).

- Sampling training, SOP templates and on-site support.

- Urgent testing lanes for critical asset protection.

Summary

AGT Labs’ Hydraulic Fluid Testing provides rapid, actionable insights into fluid condition and contamination — helping maintenance teams prevent failures, extend component life and optimise filtration strategies.