Lubricants & Oils Testing

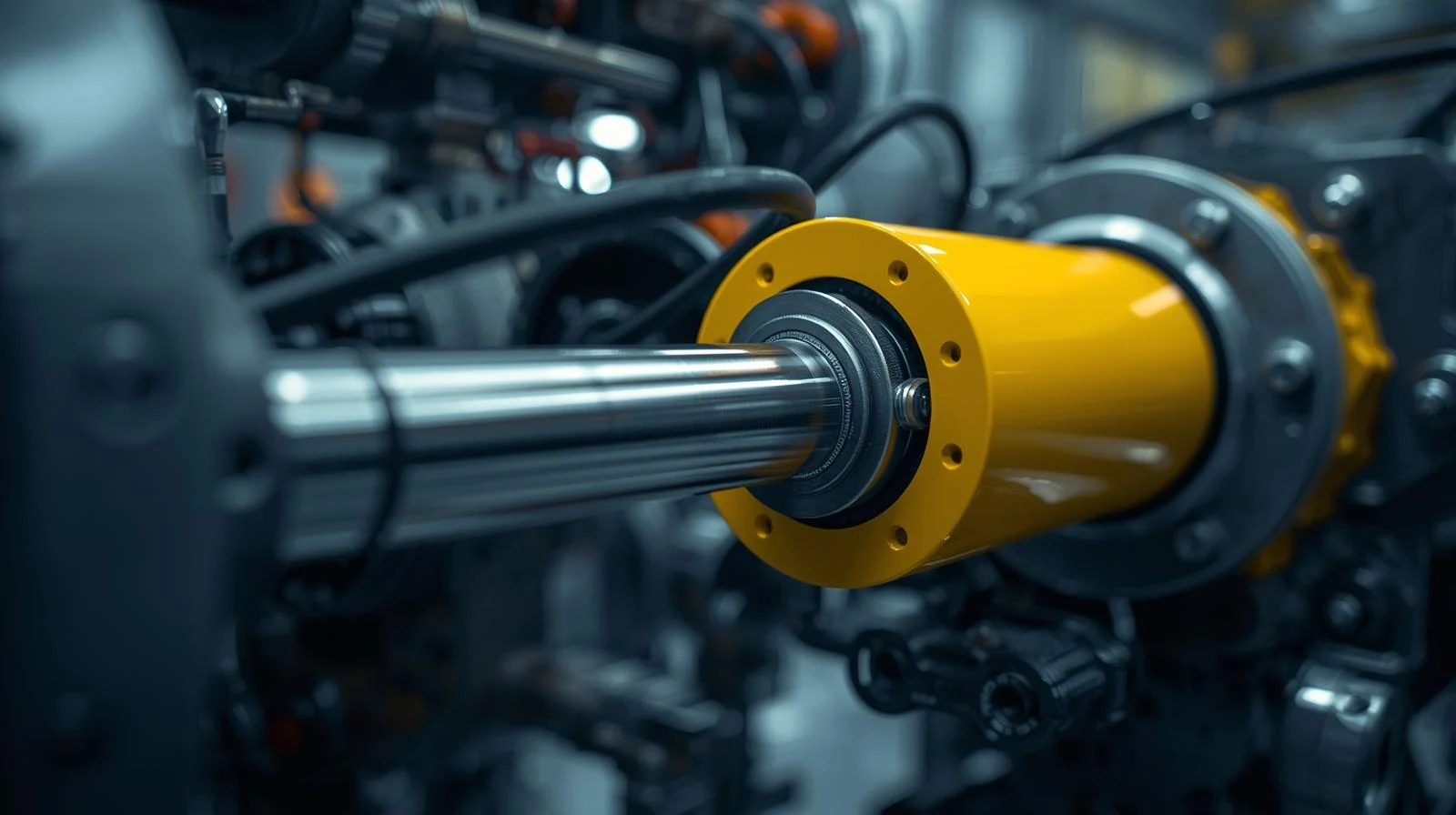

Ensuring Quality, Performance, and Equipment Protection

Lubricants and oils reduce friction, heat, and wear across engines and machinery. They support operational reliability and help extend equipment service life in automotive, industrial, and power applications.

Our laboratory provides accredited testing services based on ISO/IEC 17025–listed ASTM and IP methods, focusing on appearance, residue characteristics, corrosion screening, and basic contaminant checks.

Engine Oil

Engine oils protect internal components by maintaining lubricity, cleanliness, and stability. Accredited testing evaluates quality indicators that support condition assessments.

Key Testing Parameters:

- Visual appearance and color evaluation

- Copper corrosion (accredited method)

- Carbon residue screening

- Refractive index checks

- Non-volatile residue testing

- Basic water and contaminant detection

Turbine Oil

Turbine oils must remain clean and stable during prolonged, high-speed operation. Accredited testing supports performance monitoring through appearance and residue-based evaluations.

Key Testing Parameters:

- Visual and color assessment

- Copper corrosion screening

- Non-volatile residue checks

- Refractive index measurement

- Carbon residue analysis

- Basic particulate and water indication

Hydraulic Fluid

Hydraulic fluids must maintain stability and cleanliness to ensure consistent system performance. Accredited testing verifies key physical indicators.

Key Testing Parameters:

- Visual clarity and color evaluation

- Copper corrosion testing

- Refractive index checks

- Non-volatile material screening

- Carbon residue evaluation

- Basic contaminant and water indication

Lubricant Testing

Our laboratory evaluates lubricants using accredited ASTM and IP procedures focusing on appearance, residue, corrosion tendencies, and baseline quality indicators.

Testing Techniques Include:

- Visual and colorimetric assessments

- Copper corrosion evaluation

- Refractive index measurement

- Carbon residue determination

- Non-volatile residue testing

Testing Standards & Methods

- ASTM – Accredited appearance and residue methods

- ISO & EN – Relevant compliance references

- Visual and color evaluation

- Carbon residue and non-volatile matter testing

- Copper corrosion and basic contaminant checks

Why Choose Our Lubricants and Oils Testing Services

- Accredited testing for engine, turbine, and hydraulic oils

- Reliable results using ISO/IEC 17025–listed methods

- Certified laboratory with traceable procedures

- Clear, actionable reporting for maintenance decisions

- Fast turnaround for minimal downtime

Conclusion

Lubricants and oils testing is essential for maintaining equipment reliability and operational safety. Our accredited methods provide dependable insight into product quality, contamination, and compliance with applicable standards.